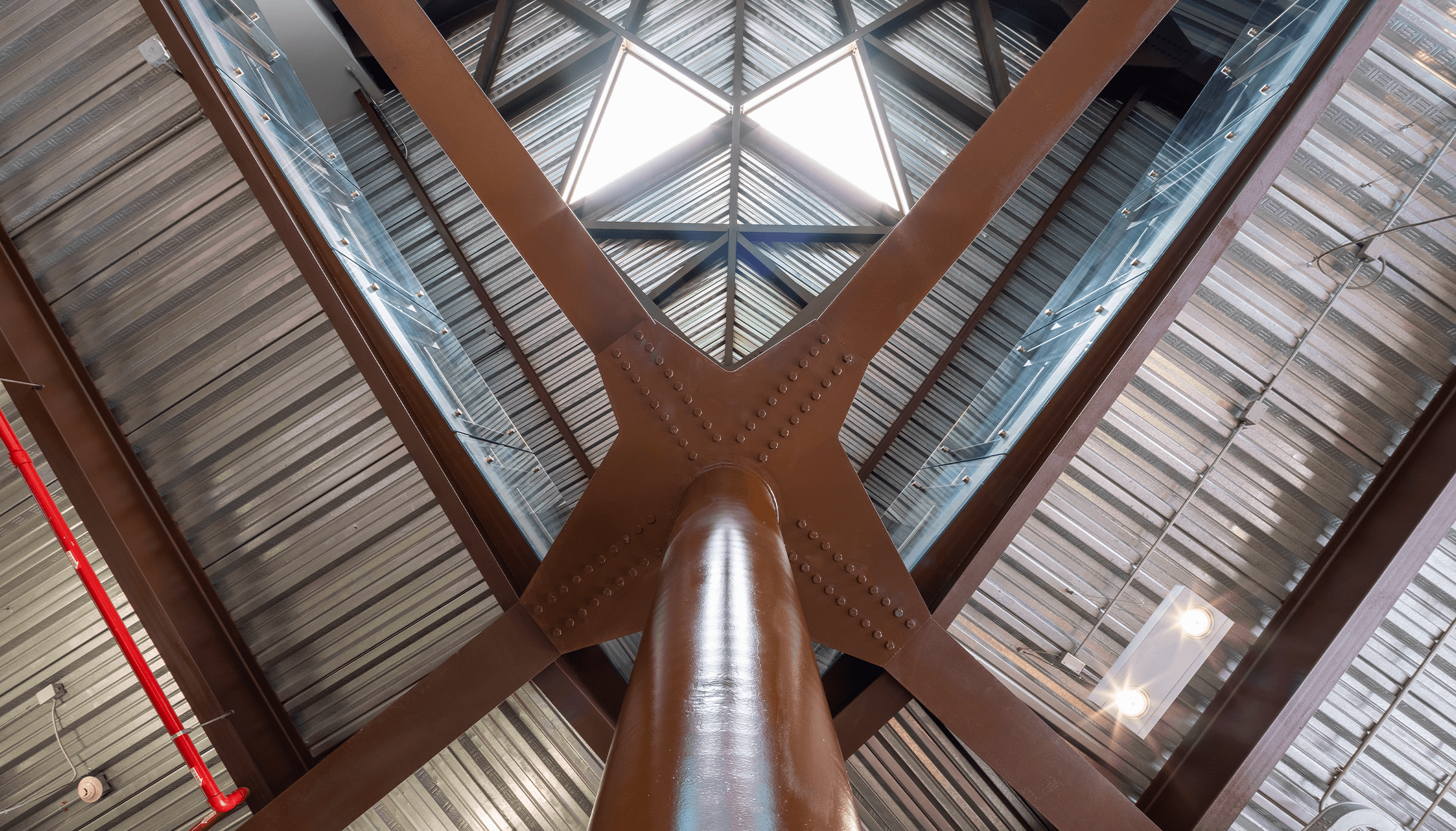

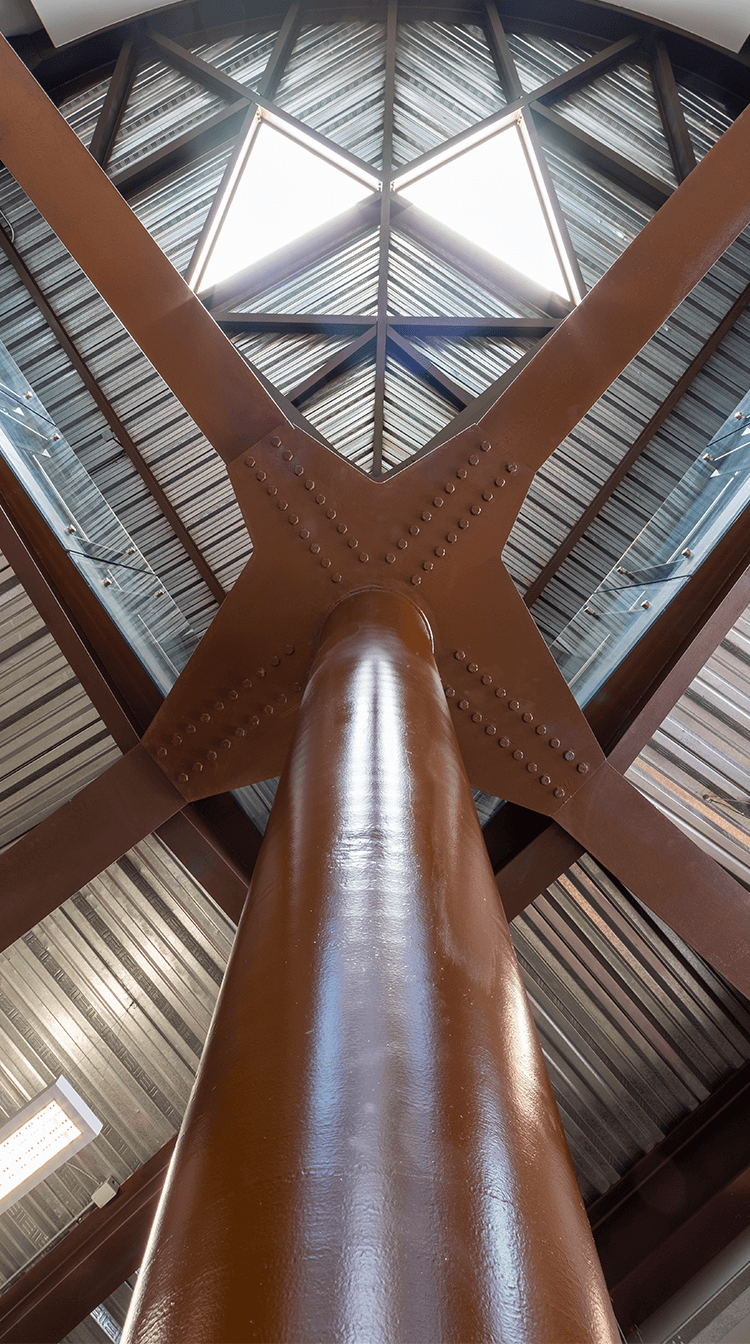

Architecturally Exposed Structural Steel

In contemporary architectural projects aiming for a modern and minimalist aesthetic, architecturally exposed steel (AESS) has become a trend. Thanks to the aesthetic and functional properties of steel, it’s possible to create visually stunning designs because structures can be fabricated in an unlimited range of shapes, curves, colors, and finishes.

AESS doesn’t aim to conceal steel behind layers of material but proudly showcases it, making it a visible and essential part of the building’s aesthetics. Highlighting both the beauty and structural integrity, whether inside or outside a building, this approach seeks to accentuate the beauty and strength of structural steel, acknowledging its role as an artistic expression.

The Architecturally Exposed Structural Steel (AESS) standards of the American Institute of Steel Construction

The American Institute of Steel Construction (AISC) has a special section for Architecturally Exposed Structural Steel (AESS), with specifications for different finishing standards that can be applied to the structure. AESS can be customized according to the project’s needs to achieve the desired effect in terms of gloss and texture.

Understanding the different categories of AESS is useful in architecture and structural engineering to ensure that all parties involved are in agreement regarding the expectations of quality and final appearance. Understanding the categories can help professionals more accurately estimate costs and construction timelines related to finishing. This contributes to more efficient resource management and the prevention of delays and cost overruns.

AESS Categories:

1. In Category 1 of AESS, attention to detail and functionality are prioritized. Here, edges are smoothed to achieve a clean and uniform finish. Welds have a seamless appearance, representing precision and structural integrity. Additionally, any welding spatter is meticulously removed, maintaining a polished and refined look. This level allows for a more rustic yet intentional aesthetic, aligned with structural needs and embracing visible imperfections, but carefully managed.

2. In Category 2 of AESS, welds exhibit uniformity and smoothness, without visible manufacturing marks. Precision is high, maintaining manufacturing tolerances at half the standard level. This level ensures a refined finish, where structural elements feature impeccable welds and a clean appearance, maintaining a high level of precision and aesthetics.

3. For Category 3 of AESS, meticulous attention to detail is given. Manufacturing marks are completely eliminated, ensuring a polished surface. Butt and plug welds are expertly smoothed and filled, enhancing the overall appearance. Hollow structural section (HSS) seams are strategically oriented for minimal visibility, contributing to a seamless look. Additionally, joint clearances are minimized, emphasizing precision and flawless finish.

4. In Category 4 of AESS, achieving a flawless finish is the goal. Weld visibility is significantly minimized, offering nearly invisible welds. Surfaces are meticulously filled and sanded, ensuring a perfectly smooth appearance. Hollow structural section (HSS) seams are completely concealed, providing a seamless surface. Welds are expertly contoured and blended, achieving a level of refinement where structural elements appear nearly perfect and aesthetically refined.

AESS offers a new dimension in modern architecture by combining functionality and aesthetics in exposed structural steel. From prioritizing functionality to aesthetic perfection, AESS categories open a world of possibilities for designers and builders in creating truly exceptional structures.

For more information on how you can take your project to the next level, don’t hesitate to contact us at [email protected]

Some Recal examples with AESS:

Source: https://www.aisc.org/why-steel/architecturally-exposed-structural-steel/